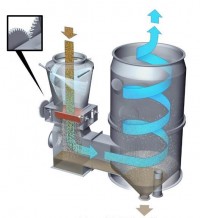

The primary function of a cyclone is to separate dust from a gas stream. After separation, the dust discharges out the bottom of the cyclone and air discharges through the top exhaust. Cyclones (or centrifugal collectors) create a ‘cyclonic’ or centrifugal force, similar to water going down a drain, to separate dust from the polluted air stream.

Wet scrubber

Wet scrubber is an industrial devices for removing dust from gases by spraying liquids. These de-dusting device compared to the others, have some advantages such as:

- Collecting flammable, explosive and corrosive dust and gases

- Cooling hot gases, therefore overall size are smaller

- Handling gases with a wide range of temperature, volume and moisture

Venturi scrubber

A venturi scrubber accelerates the gas stream to atomize the scrubbing liquid and to improve gas-liquid contact. In a venturi scrubber, a "throat" section is built into the duct that forces the gas stream to accelerate as the duct narrows and then expands. As the gas enters the venturi throat, both gas velocity and turbulence increase. The scrubbing liquid is sprayed into the gas stream before the gas encounters the venturi throat. The scrubbing liquid is then atomized into small droplets by the turbulence in the throat and droplet-particle interaction is increased. After the throat section in a venturi scrubber, the wetted PM and excess liquid droplets are separated from the gas stream by cyclonic motion and/or a mist eliminator. Venturi scrubbers have the advantage of being simple in design, easy to install, and with low-maintenance requirements. The performance of a venturi scrubber is dependent to some extent on the velocity of the gas through the throat. Because of the high interaction between the PM and droplets, venturi scrubbers are capable of high collection efficiencies for small PM. Unfortunately, increasing the venturi scrubber efficiency requires increasing the pressure drop which, in turn, increases the energy consumption.

Related Posts

- Cyclone

- Hybrid Filter

A hybrid filter system has been developed as an air pollution control device that closely integrates electrostatic precipitation (ESP) and fabric filter technologies into a durable, cost-effective device that produces superior filtration results. Its design uses a synergy between these two technologies whereby the filter bags are able to operate at high air-to-cloth (A/C) ratios than conventional pulse jet fabric…

- Electrostatic Precipitator

Electrostatic precipitators have been used in many industries; several examples are cement, steel, aluminum, copper, ceramic, tile, petrochemical and power plant. An electrostatic precipitator is a large, industrial emission-control unit. They can handle large gas volumes with a wide range of inlet temperatures, pressures, dust volumes, and acid gas conditions.